Design

Starting with the design or analysis of a design, we systematically go through technical drawings looking for flaws and inconsistencies that will show up later and could potentially be

costly to repair. Using SolidWorks, accompanied by Cosmos F.E.A., we can analyze components size, interference, material application, and geometry to add a second level of manufacturing

experience onto the process. From this point, the parts are streamed into Mastercam where we begin the fabrication process.

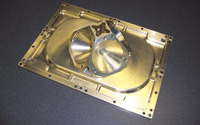

Fabrication

From Mastercam to Machine, each part is analyzed as to the most effective tool path and cutting tools to do the job in a cost effective, yet precision manner. Some machine shops tend to

think steel is steel, but we understand the cost and time loss in a part with a chip or burr in an un-welcome place. Tooling considerations are also dealt with at this time.

Into the HAAS CNC Machining Centers and the parts are on their way to becoming their intended shape.

Application Engineering

Once parts and assemblys are complete we will make all efforts to support our customers where as required. An example of this could be anything from installation of a piece of equipment;

to troubleshooting a process problem with your manufacturing staff; or even on site repairs and maintenance of existing machinery and tooling.